Are You Really Sterilizing Liquids?

When a load of liquids is placed in an autoclave, the operator selects the exposure time and presses the “start” button. The assumption that is made is that the product will be sterilized within the time period selected. But is it really an adequate exposure period?

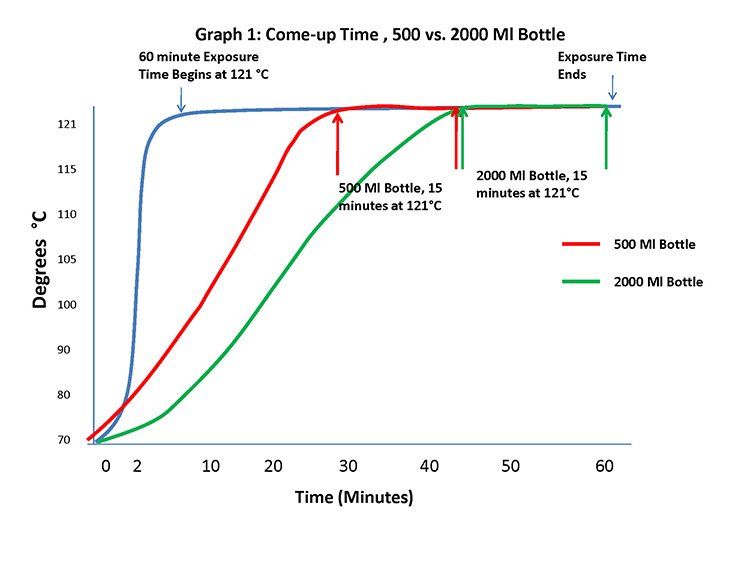

It takes time for the autoclave to reach exposure temperature and additional time for the liquid load to reach and maintain temperature.

There are a number of variables that need to be taken into account before the exposure time is selected and before the button is pressed. There are also pre-cautions and suggestions to help you achieve proper sterility.

The key variables are:

- What volume of liquid are you processing? The greater the volume of liquid, the longer it takes for the product to reach temperature. The graph below shows an example of the time required for a 500 ml volume of liquid versus a 2000 ml volume of the same liquid to reach temperature. As shown, the 2000 ml bottle required an additional 15 minutes to reach temperature due solely to the increased volume of liquid. Once the exposure temperature is reached, it must be held there until the required Fo is attained, usually 12-15 minutes.

- What is the viscosity of the liquid you are processing? The greater the viscosity, the longer it will take for the product to reach temperature. Thicker, more viscous solutions absorb heat more slowly than products such as water.

- What is the material that comprises the container? Different containers with the same volume of liquid will reach temperature at different rates. Metal containers conduct heat more rapidly than glass or polypropylene since materials of higher specific heat will conduct faster and give up that heat to the liquid contained within the container.

- How large is the load and what is the effect of load size and density? The greater the physical size of the load, the longer it will take to reach exposure temperature. If the bottles in the load are jammed together, it essentially becomes one large mass we are trying to heat. If the bottles are separated enough to allow steam to envelope each bottle in the load, there will be some variation in come-up time from bottle to bottle but, for the most part, each bottle will come up at approximately the same time as long as the variables mentioned in 1-3 are consistent. Those bottles that are positioned nearest the heated jacket of the sterilizer chamber will tend to reach temperature faster than those in the center of the load. Total exposure time should be determined based on the slowest-to-reach bottle in the load.

Finally some precautions and suggestions for safe and effective processing of liquid loads:

- When processing mixed loads, all of the variables mentioned above can affect the come-up time of the product, so the total exposure time selected for the entire load should be based on the largest volume of liquid in a bottle, located in the worst-case location and in the most-difficult-to-sterilize location in the chamber.

- A quick method for determining if the required Fo is attained is to suspend a “control tube” such as the Sterrafirm Type 6 tube that is set to change when an Fo of 12 minutes is reached. Place one of these in several of the bottles at various locations in the chamber and look for the required color change. These tubes change from red to green when an Fo of 12 minutes is achieved. The bottles you suspend the tubes in are sacrificed for sterility, but it shows that the load is achieving adequate exposure. Once you determine the exposure time for a particular load and product, the parameters will remain consistent from cycle to cycle.

- A single (or multiple) load probes, which are an optional feature on many sterilizers, can significantly reduce the required exposure time. The load probe(s) if connected to the sterilizers control and set to control its operation, will take into account the relative effectiveness of kill as the product increases in temperature at the beginning of the cycle and accounts for it when calculating the total Fo accumulated. Therefore less exposure time is required at 121°C to attain the same result.

- Only vented closured containers should be processed in a standard liquid cycle. Air must be able to escape from the container as the liquid is heated, otherwise a significant pressure differential will exist between the inside and outside of the container.